?

?

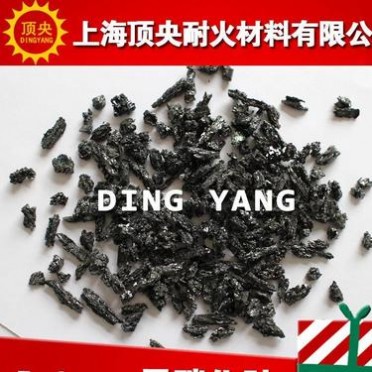

頂央五金制品噴丸強化 光飾加工用優質碳化硅

??產品介紹?

碳化硅產品介紹

?

? ? ? 上海頂央碳化硅俗稱金剛砂或耐火砂、碳硅石,主要分為黑色碳化硅和綠色碳化硅,是用石英砂、石油焦、木屑為原料通過電阻爐高溫冶煉而成,均為六方晶體。

?

碳化硅的分類

?

? ? ? 碳化硅主要分為以下兩種:

????黑碳化硅含SiC約95,其韌性高于綠碳化硅,大多用于加工抗張強度低的材料,如玻璃、陶瓷、石材、耐火材料、鑄鐵和有色金屬等。

????綠碳化硅含SiC約97以上,自銳性好,大多用于加工硬質合金、鈦合金和光學玻璃,也用于珩磨汽缸套和精磨高速鋼刀具。

?

理化指標

?

<項目

SiC

Fe2O3

F.C

97

1.2

0.3

90

1.5

0.5

比重

3.2g/cm3

棧積密度

1.53g/cm3

熔點

1800?°C

**高使用溫度

1750?°C

莫氏硬度

9.2

顯微硬度

28403320kg/mm2

線膨脹系數

1.5-2

碳化硅的應用領域

?

? ? ? 碳化硅由于化學性能穩定、導熱系數高、熱膨脹系數小、耐磨性能好,主要有以下主要應用領域:

? ? ? 1、磨料磨具--主要用于制作砂輪、砂紙、砂帶、油石、磨塊、磨頭、研磨膏。

? ? ? 2、噴砂除銹--、鋼鐵、鋼管、鋼結構不銹鋼制品的表面亞光處理,噴涂前噴砂除銹處理;

? ? ? ? ? ? ? ? ? ? ? ? ?、用于各種模具的清理;

? ? ? ? ? ? ? ? ? ? ? ? ?、半導體器件、塑封對管上錫前的清理去除邊刺;

? ? ? ? ? ? ? ? ? ? ? ? ?、醫療器械、紡織機械及各類五金制品的噴丸強化光飾加工;

? ? ? ? ? ? ? ? ? ? ? ? ?、各種金屬管、有色金屬精密鑄件的清理及去除毛刺殘渣;

? ? ? ? ? ? ? ? ? ? ? ? ?、光伏產品中單晶硅、多晶硅和電子行業的壓電晶體等方面的研磨、拋光等。

? ? ? 3、可用做制造四氯化硅的原料,是硅樹脂工業的主要原料。

? ? ? 4、工程性加工材料--用于312英寸單晶硅、多晶硅、砷化鉀、石英晶體等線切割,酞陽能光伏產業、半導體產業、壓電晶體產業工程性加工材料。

? ? ? 5、鋼鐵脫氧劑和鑄鐵組織改良劑--碳化硅脫氧劑是一種新型的強復合脫氧劑,使脫氧時間縮短,節約能源,提高煉鋼效率,提高鋼的質量,降低原輔材料消耗,減少環境污染,**勞動條件,提高電爐的綜合經濟效益。

? ? ? 6、耐火材料--利用碳化硅具有耐腐蝕、耐高溫、強度大、導熱性能良好、抗沖擊等特性,用以制成的高級耐火材料,耐熱震、體積小、重量輕而強度高,節能效果好。可用于各種冶煉爐襯、高溫爐窯構件、碳化硅板、襯板、支撐件、匣缽、碳化硅坩堝等。

? ? ? 7、陶瓷材料--用于制作耐磨、耐蝕、耐高溫等高級碳化硅陶瓷材料;碳化硅陶瓷的耐化學腐蝕性好、強度高、硬度高,耐磨性能好、摩擦系數小,且耐高溫,因而是制造密封環的理想材料。???

? ? ? 8、高溫間接加熱材料--利用碳化硅具有耐高溫,強度大,導熱性能良好,抗沖擊,作高溫間接加熱材料,如堅罐蒸餾爐,精餾爐塔盤,鋁電解槽,銅熔化爐內襯,鋅粉爐用弧型板,熱電偶保護管等。

? ? ? 9、耐磨管道跑道--碳化硅硬度僅次于金剛石,具有較強的耐磨性能,是耐磨管道,葉輪、泵室、旋流器,礦斗內襯的理想材料,此外,碳化硅也是高速公路、航空飛機跑道酞陽能熱水器等的理想材料之一。

? ? ? 10、建材陶瓷砂輪工業--利用其導熱系數 熱輻射,高熱強度大的特性,制造薄板窯具,不僅能減少窯具容量,還提高了窯爐的裝容量和產品質量,縮短了生產周期,是陶瓷釉面烘烤燒結理想的間接材料。

? ? ? 11、節能--利用良好的導熱和熱穩定性,作熱交換器,燃耗減少20,節約燃料35,使生產率提高20-30,特別是礦山選礦廠用排放輸送管道的內放,其耐磨程度是普通耐磨材料的6--7倍。

? ? ? 12、其他領域--高純度的單晶,可用于制造半導體、制造碳化硅纖維、避雷針、電路元件、高溫應用、紫外光偵檢器、結構材料、天文、碟剎、離合器、柴油微粒濾清器、細絲高溫計、陶瓷薄膜、裁切工具、加熱元件、核燃料、珠寶、鋼、護具、觸媒擔體等領域,還可以制做火箭噴管、燃氣輪機葉片等。

?

The top of the Shanghai central commonly known as carborundum emery or refractory sand, silica, carbon, mainly divided into black silicon carbide and green silicon carbide, with quartz sand, petroleum coke , wood chips as raw materials and through the resistance furnace, are the six crystal.

Silicon carbide has the following main application fields because of its high chemical stability, high thermal conductivity, low thermal expansion coefficient, good wear resistance:

1, mainly for the production of abrasives, grinding wheel, abrasive paper, abrasive belt, oilstone, grinding block, grinding head, grinding paste.

2 - , sand blasting, steel, steel, steel structure, stainless steel products, surface polishing treatment, spraying sand blasting treatment;

, for a variety of mold cleaning;

, semiconductor device, plastic pipe on the tin before cleaning to remove burrs;

shot and finishing process of shot peening, medical instruments, textile machinery, and various metal products;

the cleaning and removal of the debris from the precision castings of various metal tubes, non-ferrous metals;

, photovoltaic products monocrystalline silicon, polycrystalline silicon and electronic industry and other aspects of the piezoelectric grinding and polishing.

3, can be used as raw material to manufacture four chloride, is the main raw material of silicon resin industry.

4, the processing of materials engineering -- for 3 - 12 inches monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystal wire cutting, solar photovoltaic industry, semiconductor industry, piezoelectric crystal industry processing materials.

5, iron and steel, steel and cast iron to improve agent - silicon carbide is a new type of strong composite, so as to shorten the time, save energy, improve steel efficiency, improve steel quality, reduce the consumption of raw materials, reduce environmental pollution, improve labor conditions, improve the comprehensive economic benefits.

6, refractory materials - the use of silicon carbide has the characteristics of corrosion resistance, high temperature, high strength, good thermal conductivity, impact resistance and other characteristics, with a high level of heat shock, small size, light weight and high strength, energy saving effect is good. Can be used for all kinds of smelting furnace lining, high-temperature furnace components, silicon carbide plate, plate, support, sagger, silicon carbide crucible etc

7, ceramic materials - for the production of wear-resistant, anti-corrosion, high temperature and other advanced silicon carbide ceramic materials; silicon carbide ceramic chemical corrosion resistance, high strength, high hardness, good wear resistance, low friction coefficient, and high temperature resistance, and thus is an ideal material for sealing ring.

8, high temperature indirect heating materials using silicon carbide with high temperature resistance, high strength, good thermal conductivity, impact resistance, high temperature indirect heating materials, such as distillation furnace, furnace distillation tray, electrolytic aluminum, copper smelting furnace lining, zinc furnace arc plate, thermocouple protection tube.

9, wear resistance pipeline track - silicon carbide hardness after diamond, has a strong wear resistance, is the ideal material, in addition, silicon carbide is one of the ideal materials for the highway, aviation aircraft runway solar water heater.

10, building materials ceramic grinding wheel industry -- with its thermal conductivity, heat radiation, high strength characteristics, manufacturing kiln sheet, which can not only reduce the kiln capacity, but also increase the installed furnace capacity and product quality, shorten the production cycle, indirect material ceramic glaze baking sintering ideal.

11, energy saving - the use of good thermal and thermal stability, as a heat exchanger, fuel consumption decreased by 20, saving fuel 35, so that productivity increased by 20-30, especially in the mine concentrator with the discharge pipe, the wear resistance is 6--7 times the ordinary wear-resistant material.

12, other areas -- single crystals of high purity, can be used in the manufacture of semiconductor manufacturing, silicon carbide fiber, lightning rod, circuit element, the application of high temperature and ultraviolet detector, structural materials, astronomy, disc brake, clutch, diesel particulate filter, filaments pyrometer, ceramic film, cutting tools, heating element, nuclear fuel, jewelry, steel, gear catalyst carrier, etc can also make the rocket nozzle, gas turbine blade.

?

產品圖片?

廠家寫真?

?

?聯系方式?

?

?李好?女士??

?手???機:

?Q????Q:279****047

?郵???箱:279****047@qq.com

?地???址:中國?上海市徐匯區?漕溪北路

?網???址: